SAULEDA FOR THE PLANET

Protecting people and the environment

At Sauleda we are true to our commitment to constantly innovate to fulfill our core mission: There is a movement that is changing the world and you can be a part of it. It’s about taking care of the environment, everyone’s home, where life is born. We want to share this ecological awareness with you and that you help us promote it. Only then can we continue to fulfill our vision.

Emissions Treatment

We reduce pollution levels to a minimum, through a Regenerative Thermal Oxidation system.

Renewable Energy Generation

Through our own hydroelectric power plant and biomass boilers, we avoid the use of fossil fuels.

Waste management

We manage the collection, separation and management of chemical and textile waste from the manufacturing process.

Wastewater treatment

We clean all the water used in the factory using 3 types of treatment: physicochemical, biological and activated carbon.

Containers

Containers containing chemicals and pallets are cleaned and prepared for sale or reuse.

Reduced electricity consumption

We progressively replaced all traditional factory lighting with LED bulbs.

Sauleda and its facilities

Weaving Plant

Water treatment plant , which treats all the water used in the factory, has three types of treatment: physicochemical, biological and activated carbon.

The wastewater generated and the sludge are treated and managed by an external company in accordance with current legal regulations.

The chemicals are stored in safety cages to prevent any accidental spillage.

The pallets used to prepare customer orders are purchased from recycled wood, reducing the amount of packaging to a minimum each year.

In a world where concern for sustainability and ecology is only growing, Sauleda carries out numerous actions to guarantee its commitments, both human and environmental.

The company has 10 centres, all of them equipped and coordinated under environmentally friendly measures, where it manufactures and produces its fabrics.

We carry out environmental protection actions in all our fabric production plants: smoke treatment,

renewable energy generation, reuse of packaging, water purification, among others.

In each and every one of the company’s plants, Sauleda staff is very clear that waste must be separated in order to be able to recycle it correctly.

All of them are emptied into large containers located outside and duly signposted. Subsequently, they are collected and treated by a company approved in the management of industrial waste.

Sustainable products

Sauleda’s sustainable fabric proposal for sun protection. Loop is a sustainable fabric produced with our own textile waste from our factories. We want to give another life to fabrics, preventing them from becoming waste.

Loop is the result of a production cycle that never stops. This is Sauleda’s contribution to the circular and waste-free economy. The Loop collection features 10 different colors and prints. We solve the problems of the future from the present.

Different types of textile waste from our factories

20% Waste Mass Dyed Acrylic Fiber + 80% Standard Acrylic Fiber

Yarn created by special process

Loop End Fabric

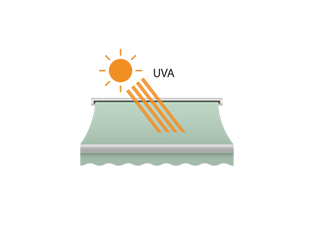

The first fabric that cleans and purifies the air through photocatalysis, removing polluting components. Designed by Sauleda’s innovation and Pureti’s technology, the fabrics suppress pollutants such as NOx, SOx and VOCs.

GREEN fabrics have a self-cleaning and mould-reducing effect. They save time, money, water, chemicals, and energy. It is Sauleda’s commitment to respect for the environment and care for people.

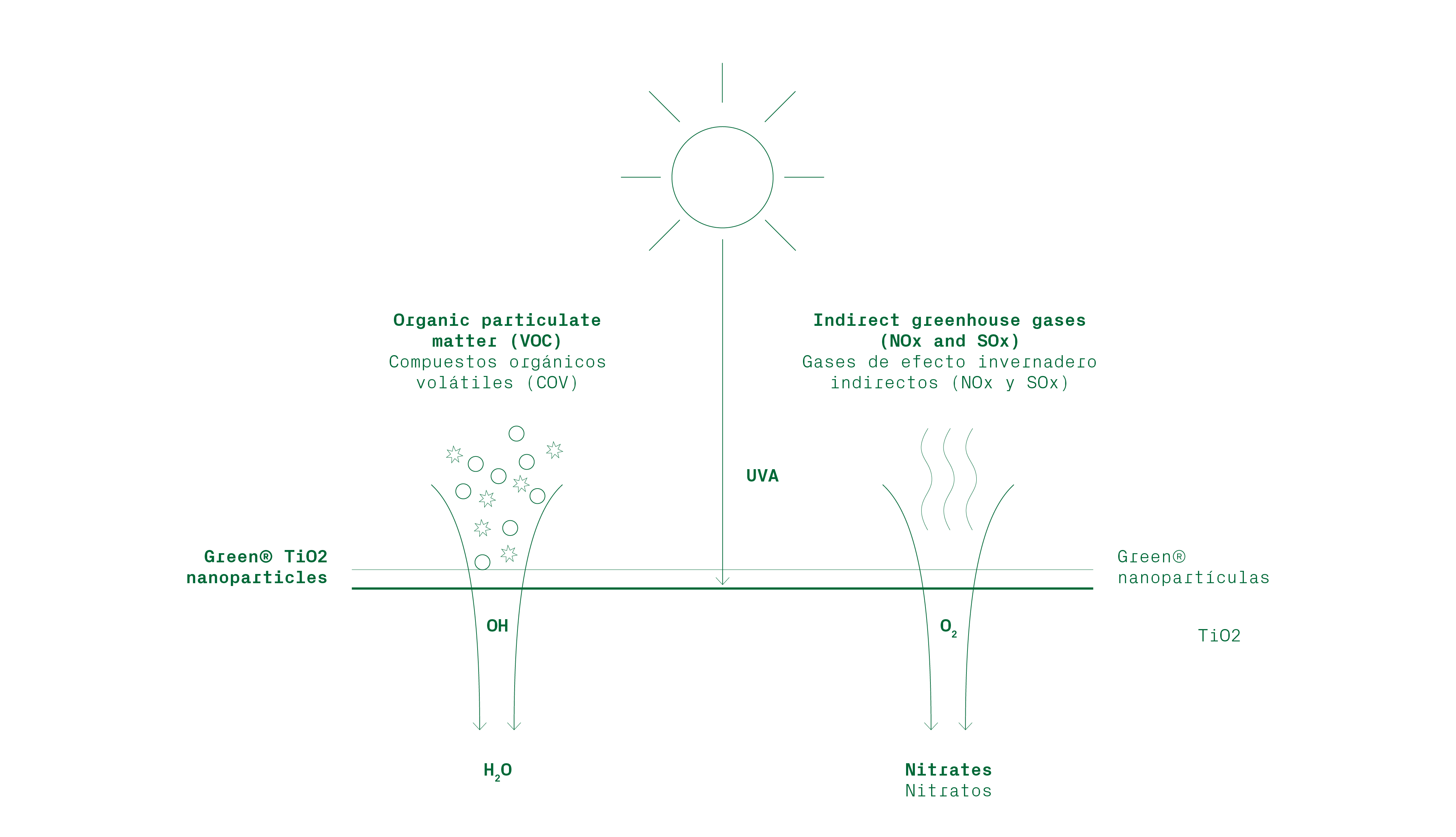

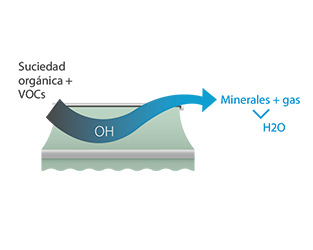

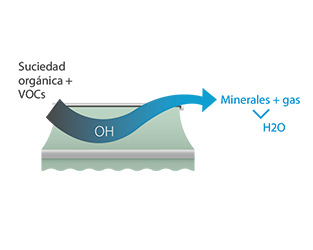

1 GREEN is a fabric coated with titanium dioxide (TiO2) nanoparticles.

2 When UVA rays hit the GREEN fabric, a chemical process begins that converts oxygen and water vapor from the atmosphere into OH and O2 cleaning agents

3 OH converts organic dirt and volatile organic compounds into mineral and gas and returns to H2O.

4 O2 reduces nitrogen oxide (NoX), one of the most harmful gases in the atmosphere, to relatively harmless nitrates.

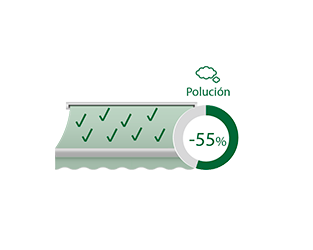

5 This process is repeated millions of times to clean the surface and the air that comes into contact with it, reducing nitrogen dioxide levels by around 55% in laboratory tests.

6 It also produces an approximate reduction of 60% in fungi and has a self-cleaning effect of around 70%*.

* These percentages are indicative and may vary depending on the conditions of the environment.